3. New PCD/PCBN

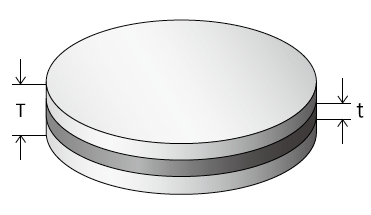

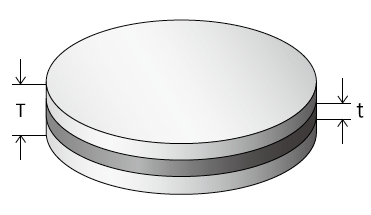

3-1) Sandwich PCD

Sandwich PCD is composed of PCD layer that is sandwiched by tungsten carbide layers in both(top & bottom) sides, primarily used for drilling application.

T : Blank thickness

t : Diamond layer thickness

PCD Grade : “FS”, “MS”, “CS”

Physical Dimension : (Half-moon of blank diameter : 51㎜, 61㎜)

Blank thickness(T)

| Diamond layer thickness(t)

|

1.5mm ±0.05

| 0.5mm ±0.10

|

2.0mm ±0.05

| 0.8mm ±0.10

|

2.5mm ±0.05

| 1.0mm ±0.10

|

Product Offer : Blank Type (51 & 61Ø half-moon) Wire EDM Cut Type (  ,

,  per customer’s spec)

per customer’s spec)

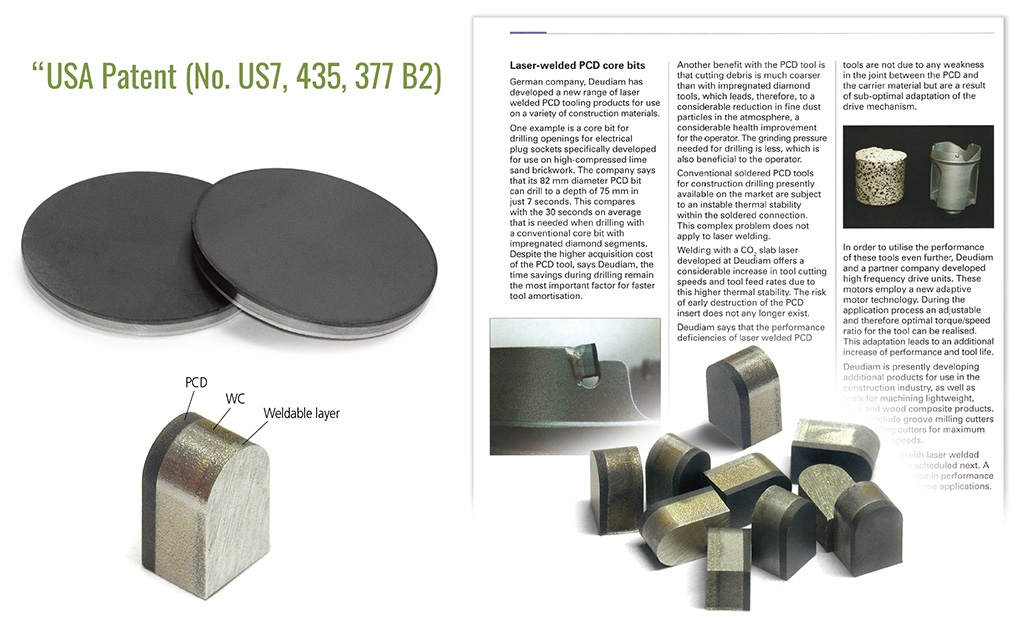

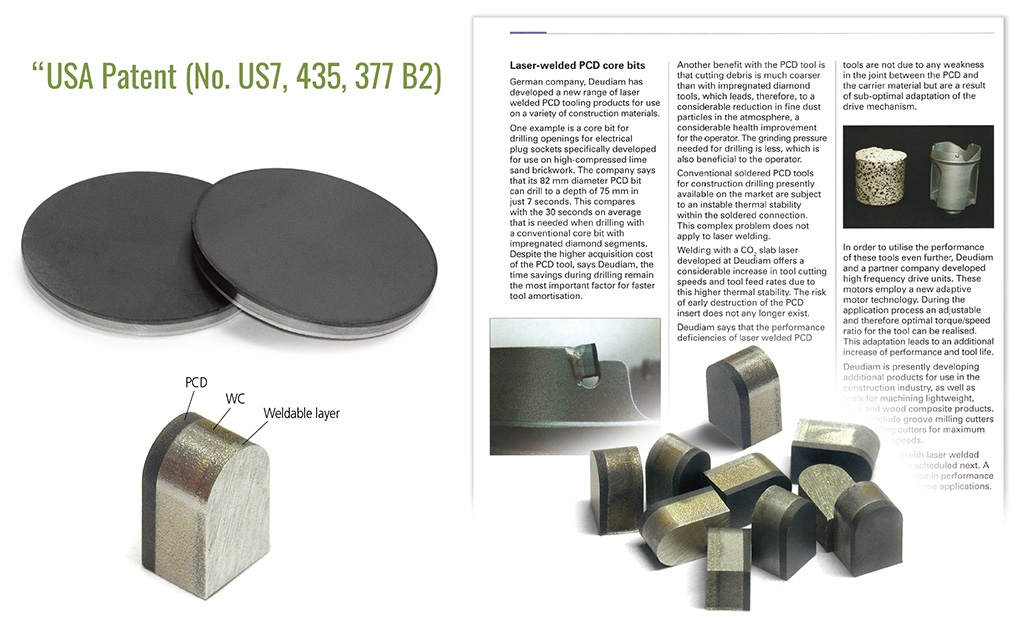

3-2) Laser Weldable PCD

An extra metal layer of PCD tungsten carbide substrate allows a new laser welding that brings lots of benefits over the conventional brazing for manufacturing PCD tipped blades.

Product Offer :

- Blank (52㎜diameter x 3.2㎜thick), (62㎜diameter x 3.2㎜thick)

- Cut-pieces (wire EDM cut)

Benefit

- Exceptionally high bond strength at the welding joint between PCD and tool body.

- No risk of tool failure from unstable thermal stability related preblems.

- Cost effectiveness from no brazing.

- Offers both less health hazardous and cleaner environmental operation.

Application for Laser Welded PCD Tools

- Saw blades for cutting tiles, rocks, cement boards.

- Saw blades for road grooving cement and asphalt.

- Core bits for drilling rocks, bricks, ceramics, etc.

- Others (like conventional PCD tools)

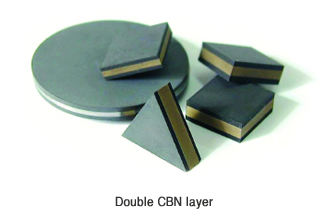

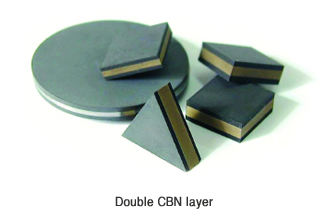

3-3) Double-sided PCBN

With a tungsten carbide material sandwiched in between PCBN materials, compared to an existing solid PCBN, it offers a higher impact strength and better bonding quality as highly rigid PCBN tools.

3-4) ADICO PCBN Cutting Tool Product Application Areas

| The range of workpiece materials that Adico PCBN can successfully machine is constantly ex-panding,

but the main material groups are:

|

| 1. Hardened steels

2. Hard facing alloys

3. Chilled cast iron

4. Pearlitic grey cast irons

|

| 5. Sintered iron

6. Superalloys e.g. Inconel 718

7. Powder metal e.g. automotive valve seats

|

| ADICO PCBN Products

|

| Successful machining applications have been established in the automotive,

aerospace, and manufacturing industries, and some examples are:

|

| High CBN-content PCBN

ADN10, ADN16

|

| ADN10 | - gray cast iron cylinder boring (GG 20/25)

- nodular cast iron tuning (GGG50, 38-42 HRC with good cylindricity & higher feed rates than other tools)

|

| ADN16 | - brake drum tuning (GG20)

- TiAl₆V₄ exceptionally good for tuning applications

- internal gear tuning with very good surface finish

- ball nose end milling (CF53, 62HRC) with extremely high edge-stability and better surface quality

- sintered geared tuning (SK72-01, 60HRC)

|

| Low CBN-content PCBN

ADN35C, ADN35N, ADN40C, ADN45N, ADN45C, ADN55N

|

| ADN 35C ADN 35N ADN 40C ADN 45N

ADN 45C

ADN 55N

| - finish machining difficult grey cast irons (milling) and hardened steels

- severe interrupted turning of hardened steels and die steels

- continuous & interrupted turning on hardened steels and valve seat

- turning applications (both continuous and interrupted) of hardened steelsand cast irons for superior surface finish

- finish turning on case hardened steels and crank shaft, cam shaft, and gears

- moderate interrupted hard turning, finish hard milling & high speedcontinuous turning It gives an exceptional surface finish to workpiece andprovides toughness to cutting tools

- grooving cam shafts & surface milling (cold work tool steel)

- mild & slight interrupted turning of gear shafts

|

,

,  per customer’s spec)

per customer’s spec)